This process of cutting represents one of the biggest technological improvements in this area. It provides advanced accuracy, speed, and automation. Also, you can process different materials with it, like metals, wood, plastic, and more. If you need a CO2 laser cutter, there are many products available on the market that can serve for various purposes.

The first thing to do when you are looking to buy this machine is to check the producer, warranty, and compare the prices. We are going to introduce you to the main features of the CO2 laser cutting machine.

What is Laser Cutting?

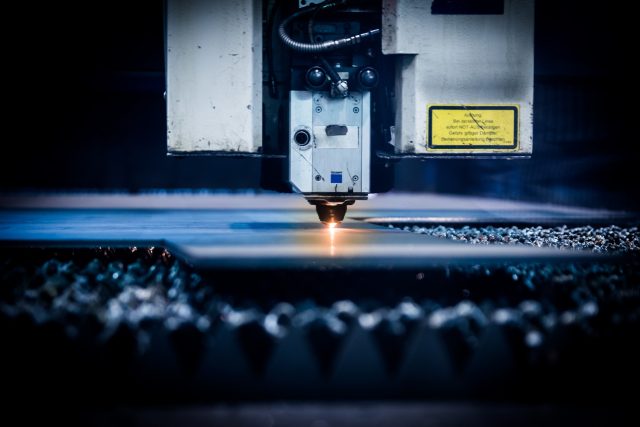

It is a process where the machine is using focused beams to cut through various materials. Besides cutting, there are also models that you can use to engrave, mark, and some other processes. The excellent feature is high accuracy, and this machine can be used to add lines that are wide only a couple of millimeters if needed.

Moreover, the combination with digital technologies provides great features of bigger production lines since you can set automations where this machine can create a lot of same units in short time. The most common option is CO2 laser.

Why is CO2 Machine So Popular?

One of the main reasons why this is the most common choice for many companies is the fact that you can use it for various materials. There are models specially designed to cut wood, plastic, glass, wood, and more. Therefore, you can easily find the right model according to your needs.

The process works in a way where the beam is created in the tube that is containing the gas in combination with electrodes. Also, we have to mention that this process is much safer when compared to many other options since the radiation is not visible.

Another important feature is that there is no contact between the parts and materials. The machine is creating a concentrated beam that is applying heat on a specific area, which is the key of the process. That provides it with such a high accuracy.

There are other benefits as well, like the fact that it is much better when it comes to the environment since there won’t be any waste left. Also, it does not need high amount of energy to operate. Moreover, it is safer than most of other cutting technologies since there are not blades.

Furthermore, there are benefits for many industries from the implementation of this technology. It can be used in the production of highly sensitive medical equipment, precious metals, and jewelry, computer chips, hardware, engraving, and much more.

Last Words

As you can see, the process is not that difficult to understand. The machine is using CO2 in combination with electrodes and mirrors to create a powerful beam that can cut through various materials. In the end, the machine is safe, with very low emission of toxic gasses, and people can quickly learn how to operate with it.